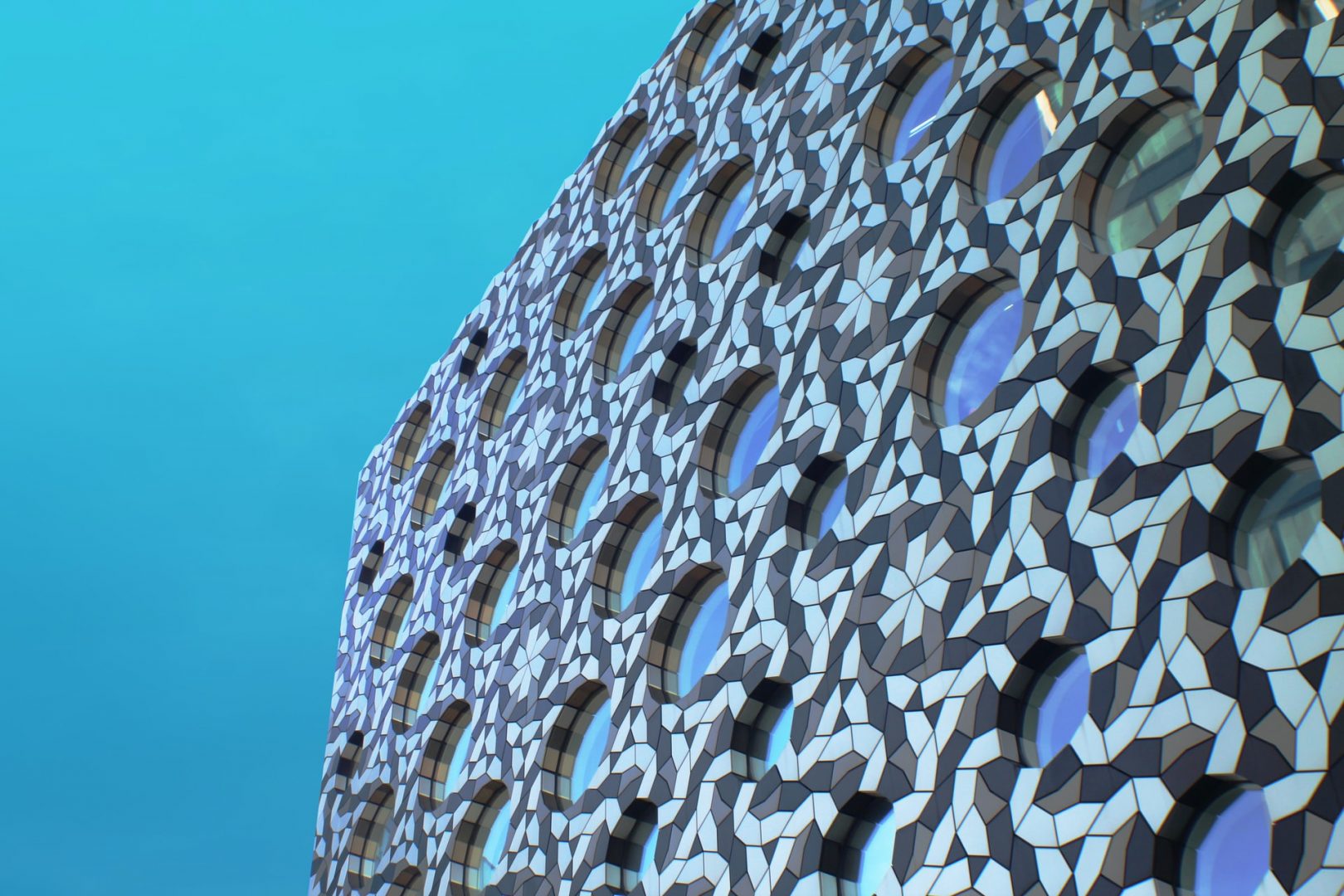

Picture a sleek, curved shopfront that draws your eye. Or a modern stadium with graceful metal arcs soaring into the sky. These designs aren’t just impressive — they’re made possible by aluminium bending. It’s a process that shapes aluminium into smooth curves, sharp angles and all kinds of custom forms. And it’s a big deal in today’s architecture, construction and manufacturing.

But here’s the thing — even though aluminium is flexible, it’s not limitless. There are boundaries to what you can do. That’s what this blog is all about.

We’ll walk you through:

- What makes aluminium easy (or hard) to bend

- The kinds of shapes and curves you can get — and the ones you can’t

- Why aluminium bending radius matters so much

- The best way to bend aluminium, depending on your needs

- Common questions and real-world advice

What Affects How Aluminium Bends?

Alloy Type and Grade

Some alloys are more flexible than others. The 6000 series (such as 6061 and 6082) is great for bending — it’s strong yet still flexible. However, other types of aluminum, such as the 2000 or 7000 series, are much stiffer and more brittle. Try to bend them too far and they’ll snap or warp.

Thickness and Shape

Thicker pieces of aluminium resist bending more. The shape matters too — complicated cross-sections or profiles with numerous details are harder to bend cleanly and may deform in the process.

Surface Finishes

If the aluminium has been painted, anodised, or has a thermal break, bending becomes trickier. The finish might crack or peel unless extra care is taken. You’ve got to match the bending method to the finish.

Length and Complexity

Long profiles can flex, twist or even sag during bending. Complex extrusions may require custom tools to prevent distortion and maintain their original shape. Planning ahead makes a big difference.

What’s a Bending Radius — and Why It Matters

Let’s talk about the aluminium bending radius. Simply put, it’s the inside curve of your bend. And it’s a make-or-break detail.

The minimum bend radius is the tightest curve you can make without damaging the aluminium. Go any tighter and you risk cracks, kinks, or a ruined profile. The actual number depends on your alloy, thickness and profile shape, but as a rule of thumb: don’t go smaller than 1.5 times the thickness. If you ignore bend radius guidelines, you could end up with:

- Cracks along the bend

- Squashed or flattened sections

- A part that just doesn’t fit or work anymore

The Best Way to Bend Aluminium: Methods and Limits

Roll Bending

This is the go-to method for smooth, large-radius bends. The aluminium passes through three rollers to get the shape. It’s great for long, sweeping curves, but not ideal for tight turns or precise angles.

Mandrel Bending

Perfect for thin-walled profiles that require accuracy. A support (mandrel) is inserted to keep the shape intact while bending. It prevents wrinkles and collapse, but it’s less effective for thicker or super-detailed sections.

Stretch Bending

In this method, the aluminium is pulled tight and formed over a mould. That tension keeps the surface smooth and the shape spot-on. It’s often used in high-end architecture but requires specialist tools.

Extrusion Bending

This one’s a bit more complex. It’s used for custom aluminium extrusions and needs careful planning to manage internal stresses. Done right, though, it delivers clean, accurate bends for even the most unique designs.

What You Can Do With Aluminium Bending

You’d be surprised how much is possible with the right tools and know-how – bend profiles with elevations up to 700mm, handle painted and thermally broken aluminium without damaging the finish, create stunning curves, including multi-directional and elliptical shapes. This makes aluminium bending perfect for:

- Facades and building exteriors

- Windows, doors and curtain walls

- Shopfronts and signage

- Structural and industrial components

What You Can’t Do — The Limits

Even the best aluminium has its limits. Pushing too far can lead to failure, wasted material and frustration.

- Trying to bend a too-tight radius? Expect cracks.

- Working with very thick or intricate profiles? The force needed might distort the shape.

- Choosing alloys with low ductility? They just won’t bend well.

- Bending heat-treated or anodised profiles after finishing? The risk of surface damage is high.

- Attempting huge curves with tight tolerances? You’ll need advanced machinery and expert support.

FAQs: What People Ask About Aluminium Bending

Can aluminium be bent without heat?

Absolutely. Most aluminium bending is done cold, especially with the right alloys.

Does bending ruin painted aluminium?

It doesn’t have to. With the right techniques, you can protect the paint during the bending process.

How do I stop aluminium from cracking?

Choose the right alloy, respect the minimum bend radius and use the best bending method for the job.

What’s the longest piece that can be bent?

You can bend lengths over 13 metres — if you’ve got the equipment and skill to do it properly.

Final Thoughts: Get It Right from the Start

When it comes to aluminium bending, understanding what’s possible — and what’s not — can save you time, money and a lot of headaches. Knowing your alloy, respecting your aluminium bending radius, and selecting the best method to bend aluminium are all key to achieving results you can count on.

The best move? Talk to an expert early on. They’ll help you work out what’s feasible, avoid costly mistakes and make your design vision a reality.

Need help with your aluminium bending project? Contact the specialists at ABS today and ensure your ideas are in safe hands.